Flat/RM 13-15 19/F, Nan Fung Centre, 264-298 Castle Road, Tsuen Wan, HongKong

Address: China operation center: Room 1305, Hangzhou Yin, No. 2030, Jianghui Road

Address: China operation center: Room 1305, Hangzhou Yin, No. 2030, Jianghui Road Binjiang District, Hangzhou City, Zhejiang Province, 310052

Post code:310052

Post code:310052  Fax:+86-579-87208230

Fax:+86-579-87208230  E-mail:info@shinemate.com

E-mail:info@shinemate.com  WeChat:jothen

WeChat:jothen

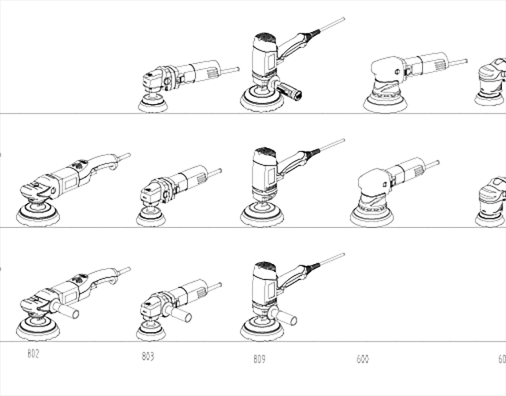

Product Comparison

Product Comparison